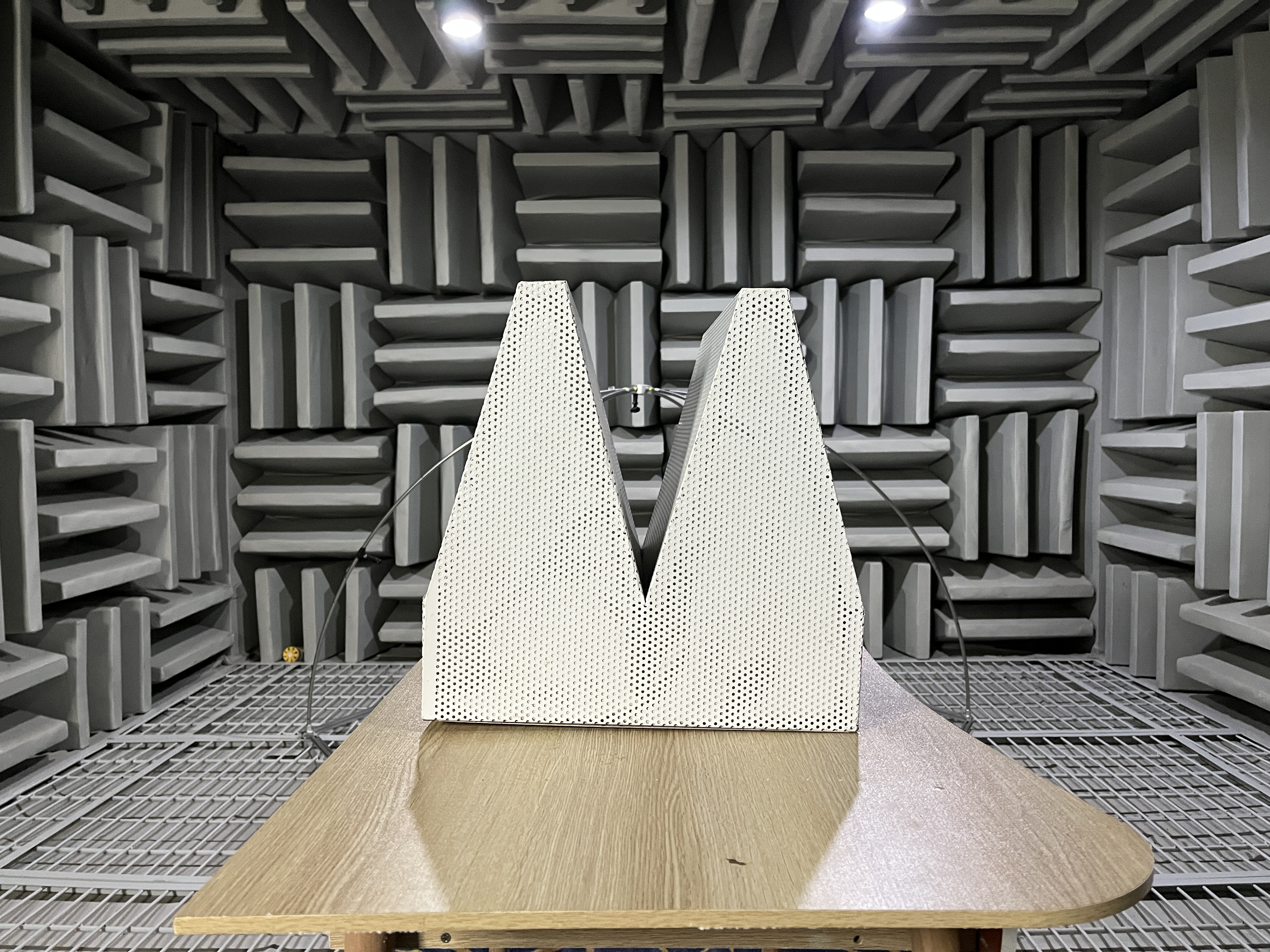

Working Principle and application of sound absorption wedge. The sound absorption wedge is a special kind of sound absorber, which requires almost all the sound waves incident on its surface to be absorbed. It is based on the principle of gradual transition. When the sound wave is incident from the tip, the acoustic impedance of the material can be well matched with that of the air because of the gradual transition of the absorbing layer. A wedge is made up of a base, which is a constant section at the bottom, and a wedge, which gradually increases from the tip. The ratio of the base of the wedge to the length of the wedge is usually controlled at about 1:4.

The acoustic wedge is mainly used to build the free sound field in the anechoic laboratory, which requires the absorption coefficient of positive incidence to reach 0.99, that is to say, the absorption of all incident sound energy. The sound absorption coefficient of the wedge is determined by the medium and high frequency. The lowest frequency at which the vertical incidence of the wedge has a sound absorption coefficient of α $0.99 is called the cut-off frequency of the wedge. In general, the cutoff frequency of a wedge is related to its length (including the depth of the cavity in which it is mounted) as follows: FL = C/4L. Therefore, the shorter the length of the wedge, the higher the cut-off frequency, but in fact, the cut-off frequency of the wedge is not only related to its length, but also related to the shape, the sound-absorbing material and so on.

Therefore, the cut-off frequency of the wedge is determined by special standing wave tube measurements. The sound absorption performance of the wedge is related to its form, length (the wedge and the bottom) , the density of the sound absorption material and the cover material. At present, all of them are characterized by the normal incidence absorption coefficient measured by the square large standing wave tube. Because of the large cross-sectional area of the standing wave tube, the cut-off frequency of the high frequency is low, about 300-400 Hz. The cut-off frequency of the low frequency depends on the length of the standing wave tube. The sound absorption characteristic of the wedge mainly refers to the sound absorption frequency characteristic below 400Hz.

In order to design sound-absorbing wedge with different advantages and disadvantages, its application must be considered. Most of the wedge are mainly used to build anechoic chamber, so the design must be done according to the required cut-off frequency, finally, its form, material and length are determined by various contrast tests. The sound absorption performance of the wedge is obtained by measuring the standing wave tube. Under the condition of the same total length of the wedge, the sound absorption performance of the flat-tip wedge is better than that of the sharp-tip wedge.

For the same wedge, the sound absorption performance of the bottom cavity depth of 200mm and 150mm is very close, but it is much better than that of the bottom cavity of 100mm in the frequency range of 160-400Hz. When the length of the wedge and the cavity at the bottom are the same, the bulk density of the sound-absorbing material filled in the wedge is 90kg/m3, which is higher or lower at the frequency of 125Hz than that of 85kg/m3, but both are above 0.99, this shows little difference. On the basis of the above results, the form, length and bulk density of the porous material used in the split can be determined and manufactured.

The above is the new synthesis of sound-absorbing split manufacturers to share the professionals on the sound-absorbing split working principle and application.